The early setting is usual measured with the penetrometer or the Vicat apparatus . This kind of measurement has some disadvantages. In the early sixties some researchers suggested to use the ultrasonic transition time as method for measuring the setting of mortars or fresh concrete. In cooperation with a German dry mix company, Schleibinger developed a special ultrasonic unit with an integrated datalogger and a special designed setup for the mortar specimen.

. This kind of measurement has some disadvantages. In the early sixties some researchers suggested to use the ultrasonic transition time as method for measuring the setting of mortars or fresh concrete. In cooperation with a German dry mix company, Schleibinger developed a special ultrasonic unit with an integrated datalogger and a special designed setup for the mortar specimen.

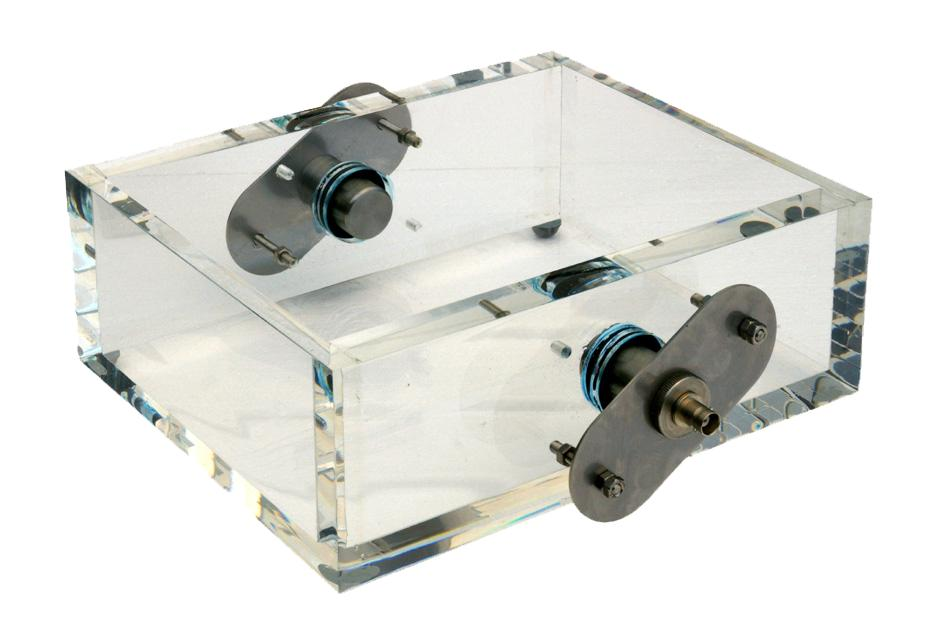

Fresh mortar is setting between two ultrasonic transducers, which are supplied with 0.25s or less pulses per second at a frequency of 54 kHz. The mortar changes, according to the setting, the ultrasonic transition time. From the beginning of first contact of the growing binder-stone, the ultrasonic sound speed increases. If there is a complete crystalline structure the change of the sound speed will be slower. Until the a further aggregation of the cement stone it increases again.

Each measurement cell is supplied with a pair of ultrasonic transducers. The Vikasonic continuously measures the ultrasonic transition time and the signal damping. The data sets are recorded digitally to a common USB stick. Each set may have more the 300.000 data values. Also date and time, the sound speed in m/s, the Youngs modulus in GPa and the signal strength in dB is calculated and recorded. Additionally the temperature inside the specimen is measured with a type K thermocouple and recorded in °C. The handling is done with one single wheel, which can be handled also with protective gloves. The system is mains or battery driven and can also be used on site for measuring structural damages. With the measurement bath C0026 you may also measure the inner damage of concrete cubes during freeze thaw cycle tests like the CIF test (see here).

The Schleibinger Vikasonic is an autonomous instrument, during the tests no PC is required. . The data may be directly imported into your Excel worksheet. The software was developed at Schleibinger and may be adapted to your special requirements.

The Schleibinger Vikasonic is an autonomous instrument, during the tests no PC is required. . The data may be directly imported into your Excel worksheet. The software was developed at Schleibinger and may be adapted to your special requirements.

Dr. B. Gerstner and F. Richartz from the Hasit central lab ( http://www.hasit.de ) made some tests to compare the Vicat and the Vikasonic method.

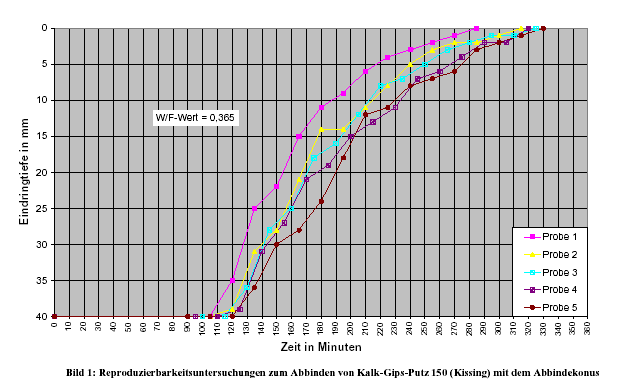

Penetration depth in mm over time in minutes - 5 times measured with same material and the same water/binder ratio

With the Vicat apparatus the deviation in percent depends on the penetration depth. With this tests the deviation range was from 27% to 40%.

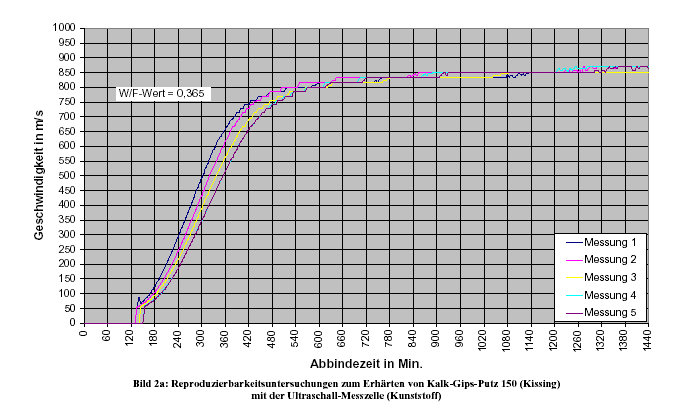

Ultrasonic sound speed in m/s over time in minutes - 5 times measured with same material and the same water/binder ratio

With the ultrasonic test the deviation was 18%. So the ultrasonic method is more accurate then the Vicat method.

Penetration depth (blue) in mm and and ultrasonic sound speed (magenta) in m/s over time in minutes - 5 times measured with same material and the same water/binder ratio

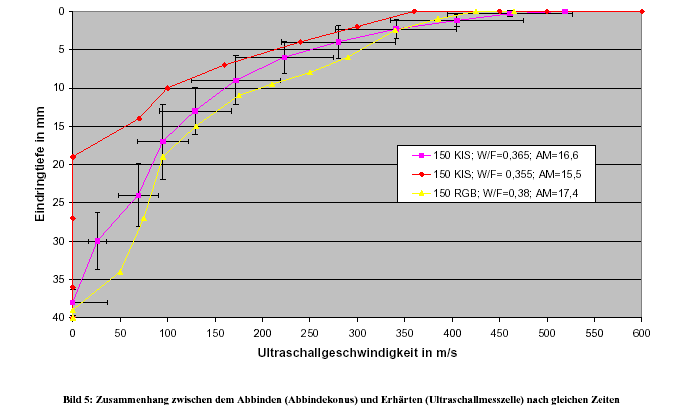

Penetration depth in mm over the ultrasonic sound speed for 2 materials (KIS) with different water/binder ratio and another material (RGB)

The correlation between the Vicat test and the Vikasonic ultrasonic method is different for various materials and mix designs. For each mix design a calibration between both methods must be done. Once you have got his curve the Vicat test may be replaced by the ultrasonic test.

The costs for the equipment are moderate higher for the ultrasonic setup, but you can do this test with less man power and you will get more objective results.

Not only for setting but also for determin the inner damage of specimen or structural element you may use the Vikasonic. For this application we recommend the 54 kHz transducers order code U0009. With some organic coupling gel (w/o grease) you may direct contact the specimen.

You may test specimen with direct contacting the transducers, or you may use a water bath. Here water is used as the coupling agent. Results are independent from the alignement of the transducers.

Two 80 kHz transducers are mounted on each side of the bath. Order code C0026. This method is defined in the CEN/TS 12390-9 "Testing hardened concrete - Part 9: Freeze-thaw resistance with de-icing salts - Scaling" and in the CEN/TR 15177 "Testing the freeze-thaw resistance of concrete - Internal structural damage"

|

Transit Time Measurement Range |

2µs to 24000µs (auto ranging) |

|

Frequency |

54 kHz or 80 kHz, others available |

|

Accuracy |

+/- 0.1µs |

|

Over Range Indication |

indicated on the display |

|

Input Sensitivity |

Better 250µV |

|

Bandwidth -3db |

10KHz .. 1 MHz |

|

Transmitter Excitation Voltage |

200V, 750V, 1000V, 1500V |

|

Pulswidth |

<= 1µs |

|

Puls Rate |

0.1...10 s |

|

Received Signal Strength |

0.1 .. 20 dB |

|

Calculated Data: |

Pulse velocity / m/s <-> input value: transducer distance |

|

|

Youngs Modulus / GPa <-> input value: transducer distance, bulk density, Poisson ratio |

|

Power Supply |

Mains or Internal Battery |

|

Mains Input |

110V .. 240V 50/60Hz |

|

Battery |

Three common AA cells |

|

Display |

Liquid Crystal 56mm x 38mm |

|

USB interface |

Host interface for a connecting an USB flash drive (2 drives included) recording: date, time, transit time (µs), pulse velocity (m/s), Youngs modulus (GPa), signal power (dB), Temperature (°C) |

|

Real Time Clock |

integrated |

|

Temperature measurement |

Typ K thermocouple |

|

Test Cell |

Holder for tranmitter and receiver, Vicat Ring as described in: |

|

|

|

* Changes that contribute to technical improvement are subject to alternations

|

Schleibinger Vikasonic with test cell, transducers and thermocouple |

U0001 |