Temperature has an big influence on the strength development of concrete. The strength development is increased with increasing temperature and lowered with decreasing temperature. The acceleration of the setting can be estimated by the Sauls law. Concrete with the same mix design has the same strength at different ambient temperatures if they have the same curing factor R.

Also more modern formulas for estimating R where suggested. See for example the standards DIN 1045 part 3 chapter 5.6.1 or ASTM C1074 - 10

Schleibinger developed, in cooperation with Bilfinger-Berger, an instrument for curing simulation. A sensor, placed in the fresh concrete measures the temperature. The temperature data are sent wireless to the Curing Simulator. Specimen of the same concrete are placed in a water tank. The temperature of the water is kept on the same temperature as the concrete part at the building site. The strength development of the specimen is the same as the strength at the building site. The measured temperature profile is recorded and may be recalled later. The temperature sensors may be connected directly or sent with a small transmitter to the curing simulator. With a built in wired or wireless modem you may access the instrument from any computer over the Internet. An optional built in cooling machine may cool down the specimen below room temperature.

directly or sent with a small transmitter to the curing simulator. With a built in wired or wireless modem you may access the instrument from any computer over the Internet. An optional built in cooling machine may cool down the specimen below room temperature.

The Schleibinger Curing Simulator at a tunneling building site in Austria. With courtesy of Bilfinger u. Berger AG

An application report you can find at the journal Tunnel , issue 01/2004 or at

|

Application |

The temperature of concrete specimen is controlled by a circulating water bath. The target temperature is measured by a wireless device with 4 thermocouple channels. A curing number is calculated. All temperatures are recorded on a compact flash card. Temperature profiles may be re-played later on. The instrument may be totally controlled by the Internet. A WEB, FtP and Telnet server is built in. |

|

Size (hxwxd) |

650x500x1000 mm |

|

Vessel volume |

up to 1000l |

|

Pump |

19 m³ / h max 95°C, 0,8kW, max. conveyor height 7m @ 4m³/h |

|

Max. Temperature |

90°C |

|

Min. Ttemperature |

5°C |

|

Heating Power |

2* 2,2kW = 4,4 kW |

|

Cooling power* |

> 1000W |

|

Temperature recoring building site |

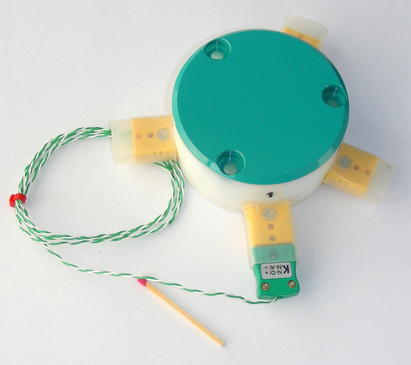

4 x Thermocouples Typ K. Temperature and ambient temperature as well as battery status are sent up to 1000m (free area) to the curing simulator |

|

Size Temperature Transmitter |

diameter 70mm, height 35mm, for field application |

|

Battery lifetime of the transmitter |

2 Litium batteries, at least 3..6 months |

|

Temperature measurement inside the curing simulator |

RTD PT100 1/10 DIN B in the circulation, add. ambient temperature RTD sensor |

|

Data recording |

all temperatures, date, time, curing ratio on a CF card as text file. |

|

Controller |

Embedded in the curing simulator, user interface colored touch screen, or remote Web-browser, grahical screen for the temperature |

|

Interfaces |

1 x 100MBit TCP/IP RJ45, CF card interface |

|

Services |

WEB/http, Telnet, FTP, no special PC software necessary |

|

Modem* |

GSM/GPRS or UMTS, SMS and e-mails as alarm messages, WEB Administration, SIM card must supplied by the user |

|

Power Supply |

3x16 A, 7kW, CEE Connector |

|

UPS |

a 12 V / 40Ah (car battery) may be connected. If the maisn power is interrupted, an alarm is sent by SMS and e-mail. The electronic will record the data up to 36 hours. The battery will be reloaded during normal operation |

|

Filter |

cleaning the circulated water, easy to clean |

|

Safety |

4 automatic fuses, 1 RCD breaker, 3 redundant over-temperature protectors. low- and high pressure switches in the cooling unit. Electronic current protection for the pump.

|

|

Curing Simulator, incl. software, elektronic,TFT-screen, pump, UPS, heating unit, power cord, filter, CF Card, network connector, valves, 1 thermocouple channel |

T0001

|

|

Wireless temperature transmitter incl. 4 thermocouples |

T0006 |

|

Receiver for T0006 |

T0007 |

|

GSM/GPRS wireless Modem f. Internet and SMS |

T0008 |

|

Cooling option for the Curing Simulator |

T0005 |