Alkali-silica reactivity is the process in which certain minerals (mostly glass type silica) in the presence of moisture are broken down by the highly alkaline environment of concrete producing a gel that expands creating tensile forces in the concrete matrix which cause cracking of the concrete. The cracking then allows more water to infiltrate into the concrete creating more gel, more expansion etc. Ultimately the concrete fails or disintegrates. Typical indicators of ASR are random map cracking and, in advanced cases, closed joints and attendant spalled concrete. Cracking due to ASR usually appears in areas with a frequent supply of moisture, such as close to the waterline in piers, near the ground behind retaining walls, near joints and free edges in pavements, or in piers or columns subject to wicking action. Petrographic examination can conclusively identify ASR. http://www.cement.org/tech/cct_dur_AAR.asp

|

(** |

|

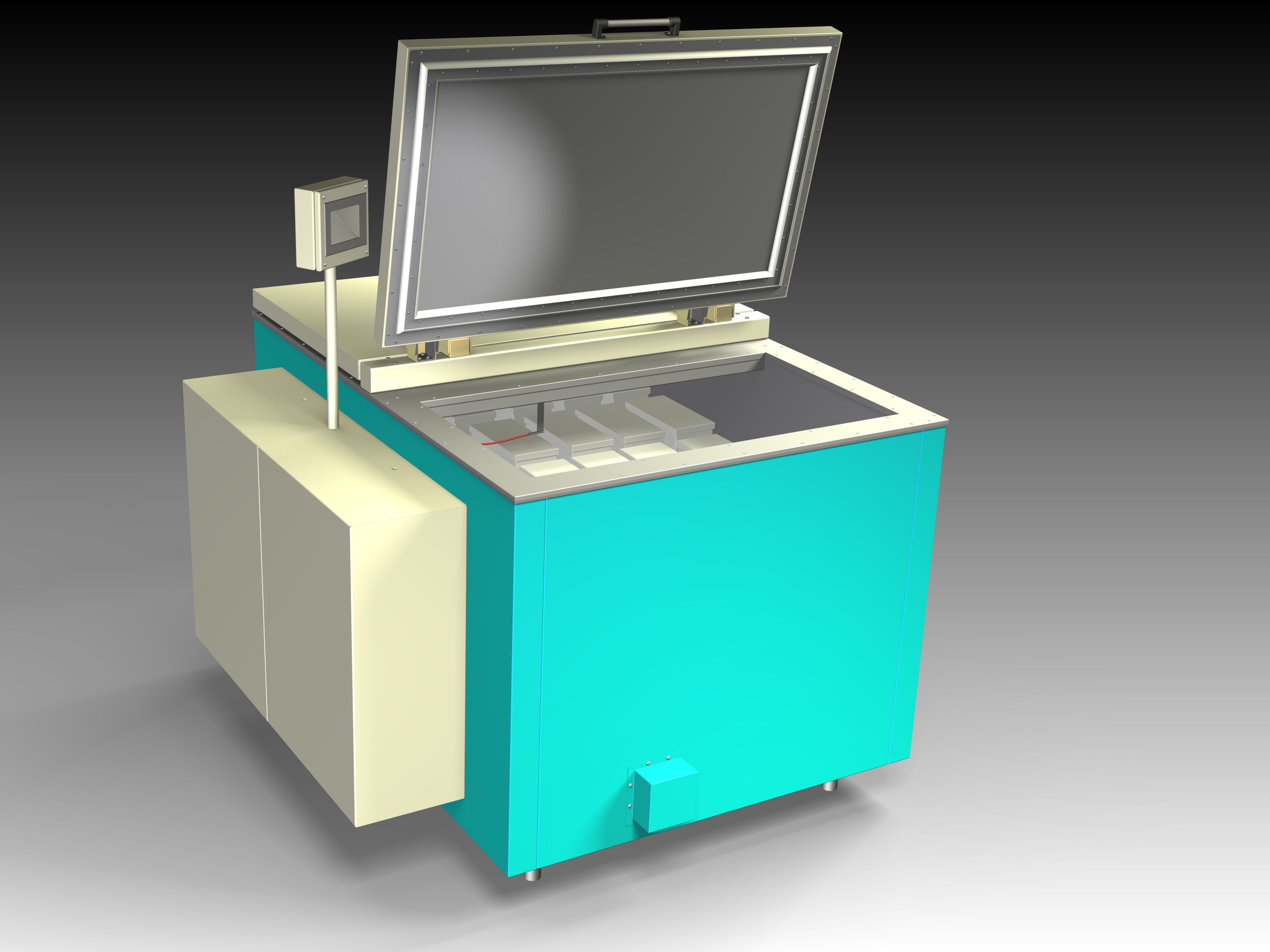

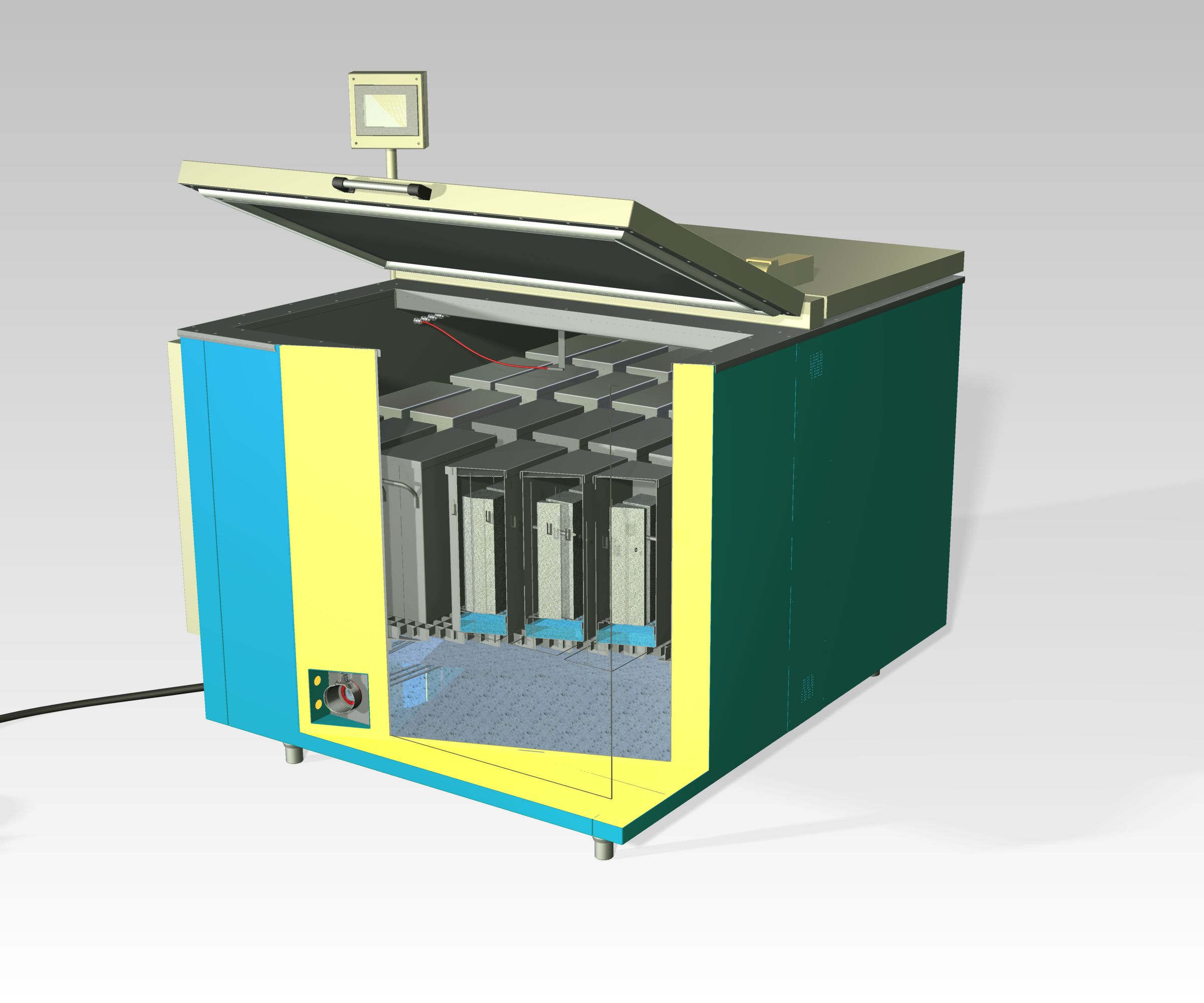

Schleibinger developed the ASR tester. In this test chamber concrete specimen are stored at a temperature between 20°C and 70°C at nearly 100% rel. Humidity according to the French standard NF P18-454 (Décembre 2004) : Béton - Réactivité d'une formule de béton vis-à-vis de l'alcali-réaction - Essai de performance and the RILEM test method TC 101-ARP AAR-4 -Detection of Potential Alkali-Reactivity- Accelerated method for testing aggregate combinations using concrete prisms - . The temperature deviation herein is below 0.5K. The temperature is registered continuously and displayed graphically. Over an Internet interface, the Schleibinger ACR-tester maybe controlled remotely.

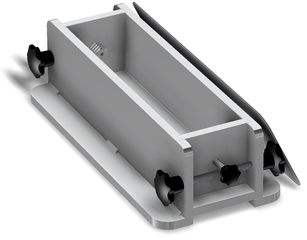

for 3 specimen with the size of 75 x 75 x 280 mm.

Inner size (l x w x h): 280 x 130 x 400 cm. Made of 1.5 mm thick stainless steel, complete welded, pickled and passivated. Lid with drip-down tin. Removable grating for concrete specimen at 50 mm level. Specimen

spacers at 260 mm height. Two handhold's at the length sides. A maximum of 24 containers (in total 72 samples) fit into ASR reactor. Order code K0002.

For temperatures below 40°C we recommend the additionally power fog system which makes extreme fine fog and nearly 100% rel. humidity also at low water temperatures. With a high pressure pump and special stainless steel nozzles. The size of the droplets is smaller then 30 micron. The fog function may be controlled with the ACR control unit by duration and intensity. Fog power about 1.2 l /hour. Protected against Legionella and similar hazards by an automatic UV-C lamp embedded into the water reservoir. This lamp is only active when both lids are closed. Warranty pump 2 years, nozzles 2 years. Order code K0003.

for specimen 75x75x280 mm. Made of 10mm thick stainless steel, weight 11 kg. Order code K0113.

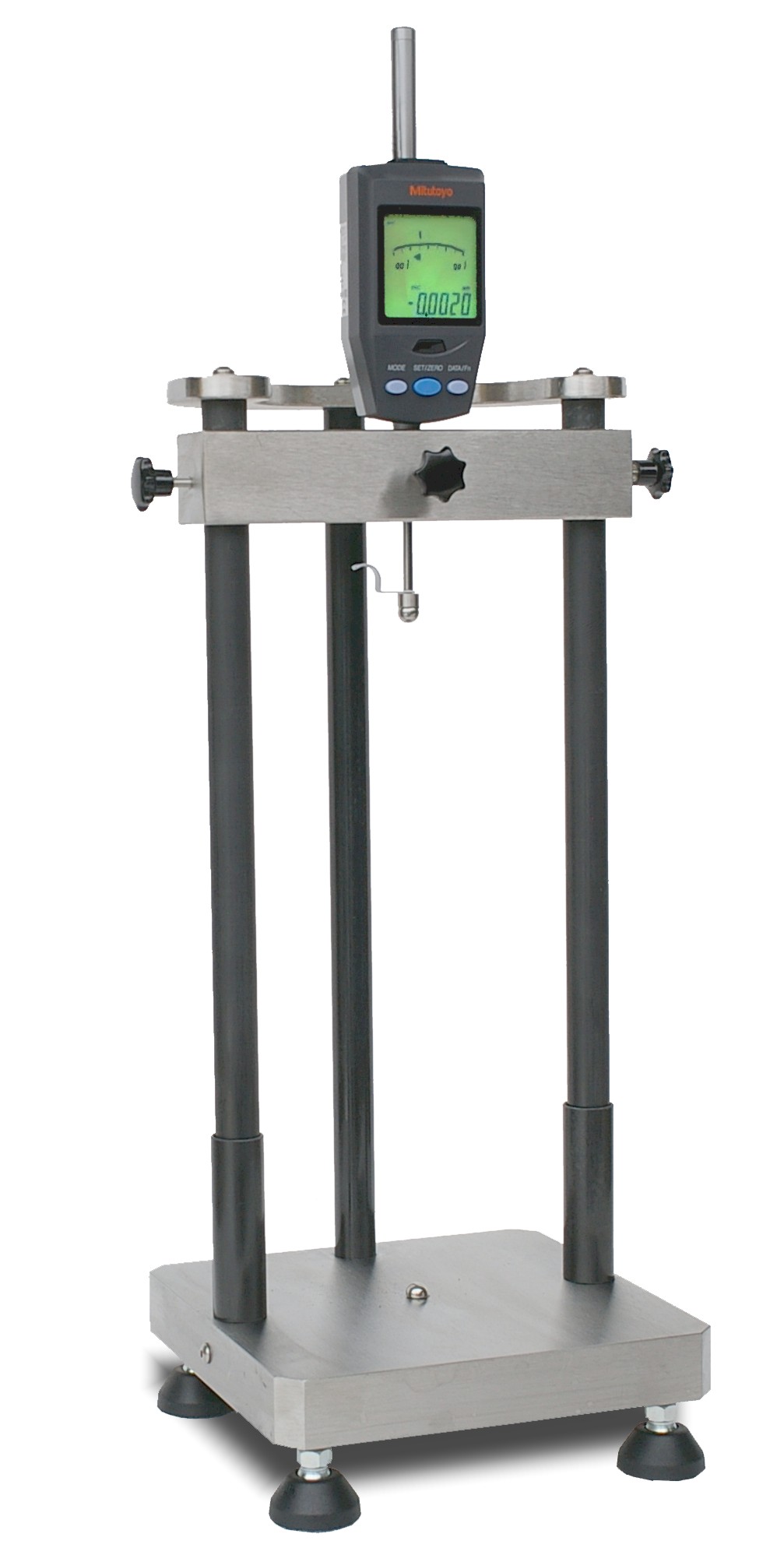

for measuring the length change of the specimen 280 x 75 x 75 or cylinders 300 x 150mm or similar. There is a socket in the base plate for fixing a 10 mm ball. Including a digital probe. Resolution 0.5 mikron, accuracy 2.6 mikron. Including a carbon made reference bar 280 mm (or 300 mm, others on request) . Order code S0111.

14 mm hexagon bolt, central hole M5 (5mm) with countersink 9 mm x 45°, stainless steel 1.4305. Order code S0115.

Figure below: Anchor-bolts for the specimen

| Application | Storing of ACR test containers at 60°C and nearly 100% rel. Humidity according to RILEM/TC-ARP/01/20 and ASTM C1293 and modifies ASTM C1293 at 60°C |

| Net. size (lxwxh) | 1500 x 1100 x 950 mm |

| Water level | 190 mm |

| Shelfs for the test container | two |

| Inner cabinet | stainless steel |

| Lid | 2 ca 750 * 120 with torque compensated hinge |

| Sensors | RTD PT100 1/10 DIN B |

| Heating | 2 x 6 kW 3*230V(or 400V) with over-temperature protection |

| Controller - heating | 2 solid state relays 3 phases |

| Controller | Remote cabinet for wall mounting |

| User interface | Colored touch-screen with online graphic |

| Interfaces | Ethernet /TCP/IP for control and data recording. |

| Weight | ca. 500 kg |

| Mains connection | 3 * 32 A / 230/400 V, CEE plug (please ask for other voltages and frequencies) |

| AAR/ASR Tester | K001 |

| AAR Specimen Container | K002 |

| AAR Fog System | K003 |

| AAR mould | K0113 |

| AAR shrinkage gauge | S0111 |

| AAR reference anchor | S0115 |